Demand Driven: DDMRP or DDSCM?

The term DDMRP has been around since 2011 and has received much attention in recent years. The promises are big: improved service levels, inventory reductions of 30-40%, shorter delivery times (up to 80% reduction!) and minimal costs. Are the windows in your Supply Chain department already fogging up?

DDMRP is based on the fact that variability has a negative effect on the performance of any system, e.g. a production line or a distribution system. It therefore seeks to reduce variability by applying dynamic stock buffers at specific decoupling points. Smart, as the nervousness of a poorly designed MRP systems and the bullwhip that quickly develops in classically controlled multi-echelon supply chains is ill-famed across many industries.

DDMRP is pushed by the Demand Driven Institute with its own conferences, well-known gurus that act as sponsors, software certifications, etc. The founders of this institute will endlessly preach to whoever wants to listen. However, the approach has thus far not been widely embraced by the Supply Chain world. Will DDMRP turn out to be another hype destined to fade away over time? That would certainly be an unnecessary shame as the methodology has a lot to offer. Nonetheless, we believe that there are two apparent reasons why DDMRP has not really gained traction yet.

Problem 1: dogmatism

DDMRP preachers almost elevate it to a religion, including the accompanying dogmatics. Great if you are already reformed, but difficult if you are more of a wait-and-see type. For example, by applying DDMRP you would “no longer have to rely on unreliable forecasts”. Of course this is great news, until the term “ADU” or “Average Daily Usage” suddenly appears. Who can explain the difference between a forecast and the ADU? The moment this ADU is being manipulated into “DDS&OP” in order to control pre-builds for example, is when the atheist inside me is slowly waking up…

Problem 2: applicability

Nobody claims that DDMRP fits all situations, but it is strongly suggested that it can be applied very broadly. This simple technique that can be implemented in five steps, including certified standard software? The same standard solution for job shop environments, the chemical industry, pharmaceuticals,…? Can 50 years of differentiated supply chain theory be pushed aside so easily?

Of course not. DDMRP is an interesting methodology based on a number of smart principles that can generate good results in specific situations. For example the demand may vary but on average it must be fairly constant, because then the ADU will remain more or less correct. If this is not the case, you will have to intervene manually and the dogmatics will start to squeeze. It appears that there are certain conditions that must be met before the standard DDMRP approach can really add value.

Cherry picking

So what is the solution? As expected, the answer is more complicated than the preachers would have you believe. Let’s start with the question whether you suffer from the specific problems that can be solved with DDMRP. Subsequently, you will have to determine whether standard DDMRP could work in your specific situation. With two positive answers, the die is cast and you can get started. Bingo!

In many cases however, one or two of the answers will not be a full yes. But don’t panic, what we now need is creativity and a true understanding of the dynamic behaviour of supply chains. Instead of the standard DDMRP solution, a structural approach like Demand Driven Supply Chain Management (DDSCM) is required.

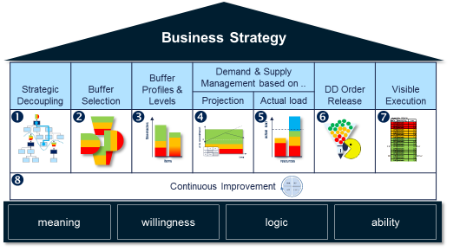

DDSCM starts by clearly defining the objectives: which problem do we want to address and what causes lay at its roots? Subsequently, elements from the Demand Driven toolbox are selected in a logical manner, such as dynamic buffers, capacity stocks, workload control, sprint times etc. With the systematic approach of DDSCM you can find solutions for very diverse supply chains in almost all industries. The promise fulfilled, but not always with the standard solution as sometimes suggested. The world just isn’t that simple.

Conclusions

DDSCM is a powerful methodology and is widely applicable. The specific DDMRP solution is standard and simple, but can therefore not be applied in all situations. So don’t be tempted by a dogmatic solution for something that may not even fit your problem statement! The answer is a combination of cherry picking and combining the selected elements in such a way that the total solution fits your situation. And addresses the problem that you had in mind in the first place!