The Wheel of Five: Eliminate unnecessary variation in supply and demand

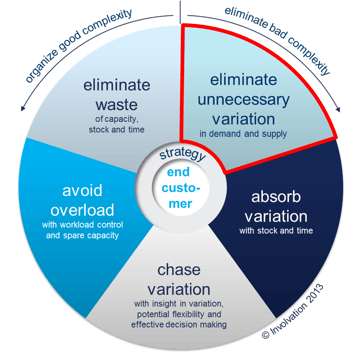

To help organizations recognize and effectively deal with good and bad variability, Involvation has developed the Wheel of Five for Supply Chain Management. This is the final part in the series of five articles about the Wheel of Five.

A s explained previously in this series, variability negatively impacts the performance of every system. Therefore, in order to improve system performance, it is necessary to reduce the variability – and there’s no better way to start than by reducing the source of all variability: variation. After all, no variation means no uncertainty, let alone variability.

It’s no coincidence that the Lean and SixSigma methodologies are so focused on reducing and eliminating variation. However, the aim is not to rigorously eliminate all variation. After all, variation can also improve the customer experience and/or be inextricably linked to the market in which a company operates. In that case, this is referred to as ‘good variation’ and it will need to be organized. Adding variation to the market can even create a competitive advantage if you know how to organize it while your competitors are still struggling to cope with the existing variation.

Time aspect

In this context, examples can include things like variation in the arrival rate (the speed of demand) and variation in the service rate (the speed with which this demand can be met) – i.e. variation in supply as well as in demand. People often think of variation in terms of the quantity aspect, but the time aspect (when the variation occurs) is equally important, if not more so. The simple example below illustrates the importance of the time aspect.

Understanding the customer need

Understanding the customer need

Imagine a situation in which the weekly demand is always for one hundred pieces in one go, but the demand can arrive on any day of the week. In this case, there is zero variation on a weekly basis but huge variation on a daily basis. It could be challenging if you are expected to meet the demand in full within the space of one day, whereas it’s easy to do so if you are allowed a week. In other words, in order to eliminate variation it is important to have a clear understanding of what your customers want in order to align your service model. This is what they have done at 247TailorSteel.

“Thanks to optimally aligning our service with the wants and needs of our target group and allowing our customers to place their orders through our online portal called Sophia, we are able to offer a high-quality service experience without unnecessary waste,” says Frank Gelen, COO of 247TailorSteel. 247TailorSteel’s advanced Sophia portal offers customers a fully digitalized ordering system for custom-cut metal plates, tubes and bent products. With this service, the company is actively targeting clients that have a short-term need for customized metal components.

247TailorSteel absorbs much of the remaining demand variability through dynamic planning and late binding in combination with differentiated delivery times. Besides that, in what initially appears to go against its concept, the company consciously serves a limited number of make-to-stock customers. “In the near future, we intend to make better use of this stock as part of a more organized approach to absorbing residual variability,” states Frank Gelen. “If you make haste when you have time, you’ll have more time when you need to make haste.”

Also read part 4:The Wheel of Five: Eliminate waste of capacity, stock and time of the Wheel of Five of supply chain management.