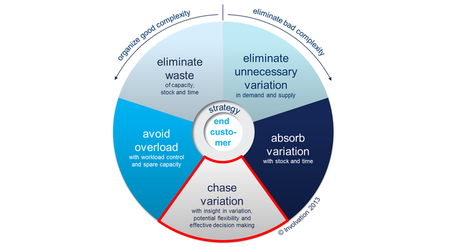

The Wheel of Five: Manage predictable variation with effective decision-making

To help organizations recognize and effectively deal with good and bad variability, Involvation has developed the Wheel of Five for Supply Chain Management. This third part in a series of five articles is about effective decision-making.

‘Variability will always degrade performance of a production system,’ according to Hopp & Spearman. ‘If you don’t reduce the variability, you will pay the price in the shape of depletion, high stocks and/or long and unreliable lead times.’ In other words, it makes sense to minimize the variability. But what exactly is variability?

Variability occurs when there is a mismatch between the variation in demand and the variation in supply. Therefore, the most ideal solution is to either eliminate or absorb the variation that causes the variability.

If that is not completely possible, you will be left with residual variation. In that case, it is wise to synchronize the variation in supply and demand. You will still be left with variation, but no variability. This often comes down to managing the demand variation with flexible capacity – the possibility to increase or reduce capacity, either temporarily or fundamentally.

Dennis Pronk (pictured) from Involvation: ‘To do this, you need reliable insight into the likely demand variation, the flexibility to manage this and – last but not least – an effective decision-making process in order to take the necessary action. As a result, IBP, S&OP and forecasting clearly have a place in this Wheel of Five as a way of organizing and feeding the decision-making.’

Dennis Pronk (pictured) from Involvation: ‘To do this, you need reliable insight into the likely demand variation, the flexibility to manage this and – last but not least – an effective decision-making process in order to take the necessary action. As a result, IBP, S&OP and forecasting clearly have a place in this Wheel of Five as a way of organizing and feeding the decision-making.’

Short-term vs long-term decisions

The type of decisions that an organization has to make in a weekly, monthly or quarterly cycle depends on the reaction times of the capacity adjustment and the reliability of the demand visibility and supply visibility. In the case of shorter-term decision-making, you can often benefit from insights into current orders and into changing demand at customer level. These insights enable effective decisions to be made about specific capacities (such as overtime, shift planning) and stock levels that can generally be implemented quickly. In the case of longer-term decision-making, it is about more fundamental changes to capacity. The longer reaction time means that reliable forecasts are essential.

They have understood this well at DSM Food Specialties (DFS) in Delft, where they have two separate demand forecasts – one for a six-month horizon at customer level, and another for a 24-month horizon at business segment level.

Roger Kerckhoffs, Supply Chain Improvement Manager at DSM, comments: ‘We realized that we lost sight of the big picture when extrapolating from a detailed forecast per customer to a 24-month horizon. The 7-month to 24-month forecast at business segment level is more suitable in the case of trends or new product introductions. This ‘roughly right’ forecast makes these topics explicit, resulting in a better guide for decision-making about things like capacity expansion. Our forecasts are generated statistically, then the detailed forecast is validated by account managers and the segment forecast by business managers.’

Timely communication of changes in demand

However, in a dynamic and complex environment with lots of variability, the forecast is not the only important element according to Kerckhoffs: ‘We can’t expect the forecast to do everything. Above all, it’s important that we don’t get bogged down in the details. We also need to focus on communicating significant changes in demand as quickly as possible. We have now set up the process based around that principle, in addition to having improved the flexibility of our supply chain in order to cope with the demand variability.’

>> Read also part 4: The Wheel of Five: Eliminate waste of capacity, stock and time