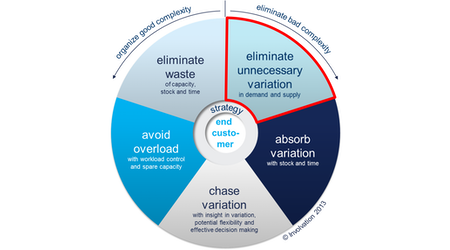

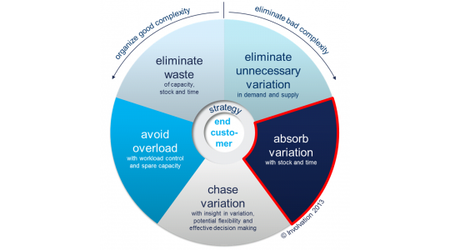

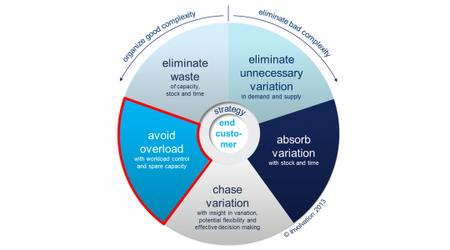

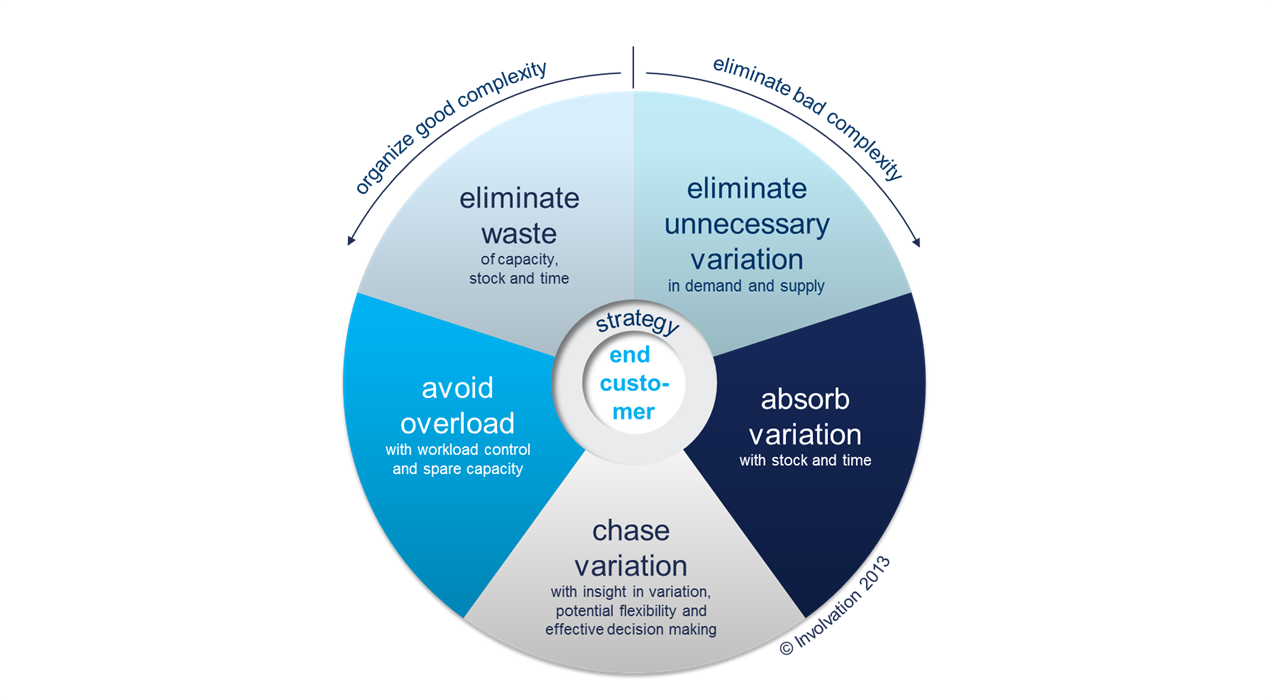

5 ways to manage complexity in your supply chain

Today’s supply chains have become extremely complex, and many businesses are struggling to cope. The good news is that much – if not most – of that complexity has been self-created. And if you can create something yourself, you can also stop creating it.

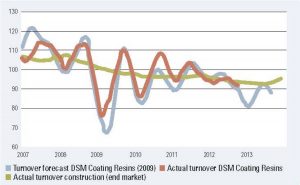

.jpg)