Nurturing Excellence: How Involvation Set Up the Supply Chain Learning Program at Rituals

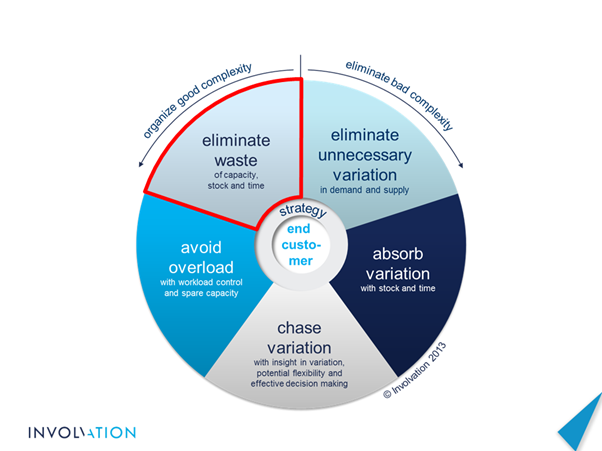

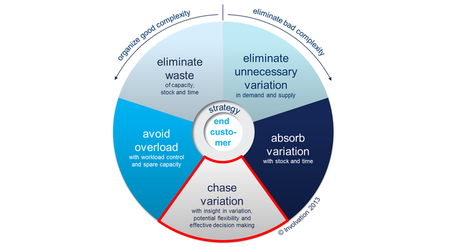

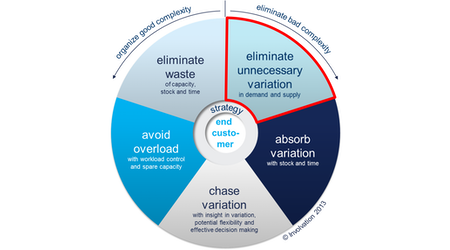

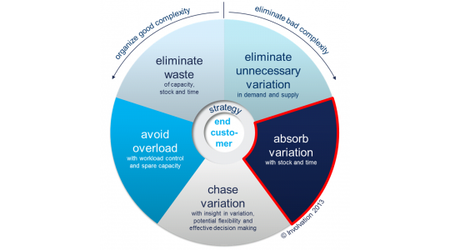

Supply chain development is essential for a fast-growing brand like Rituals. Building on a long-term partnership, Involvation and Rituals launched the first Rituals Supply Chain Academy in 2023. Here, Jeroen Scheepers, Partner at Involvation, explores the Academy’s co-design around Rituals’ end-to-end supply chain, and why a supply chain...

.jpg)